Axle Spacing Effect on Load Distribution and Ride Stability in Semi Trailers

Technical analysis of how axle spacing influences load distribution, suspension dynamics, and overall stability in multi-axle trailer configurations.

Suspension Geometry

Vehicle Dynamics

📅 Published on 2025-11-10 | ✍️ Semi Trailer News Engineering Desk

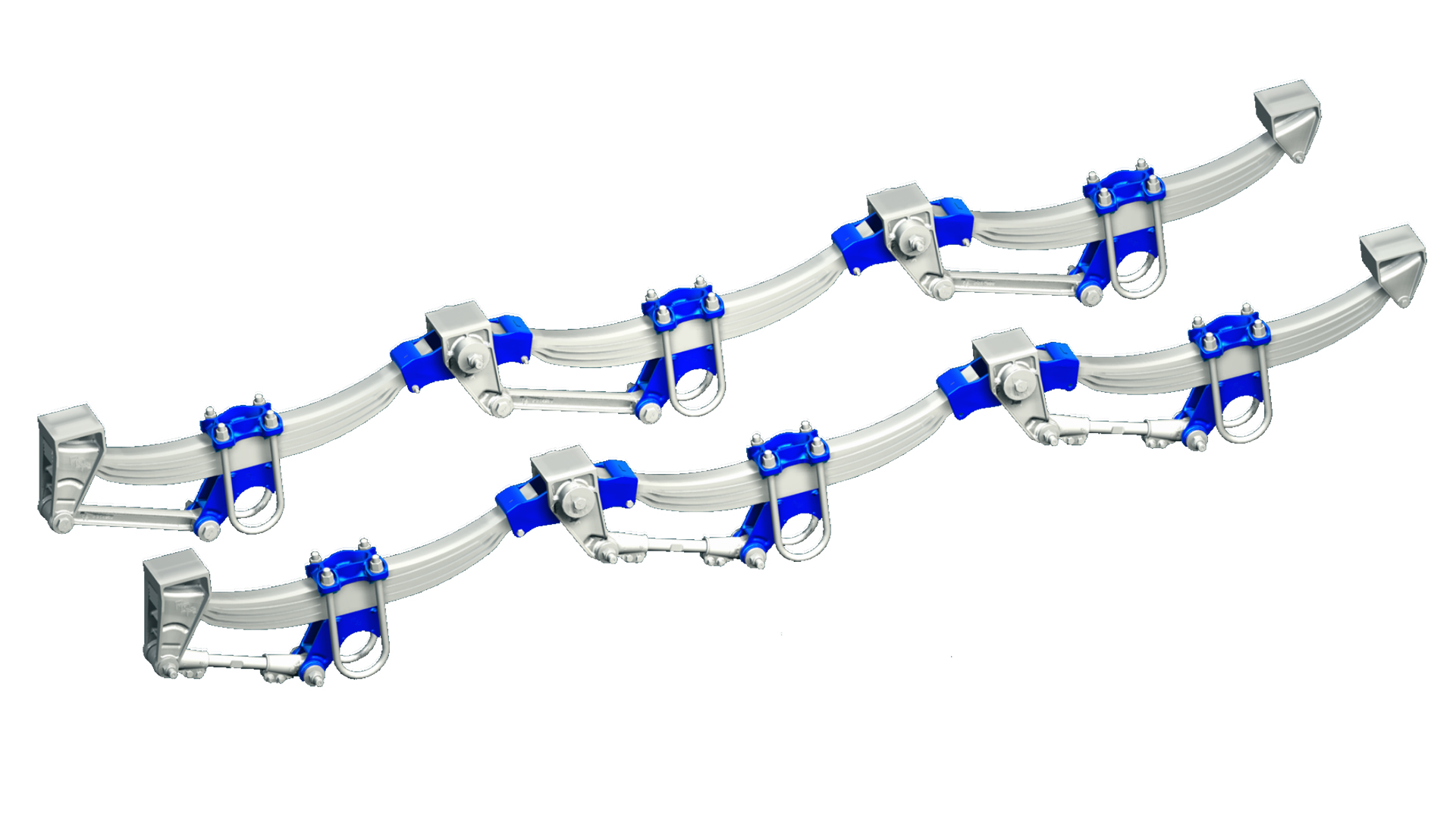

Image: Dynamic load distribution model of 4-axle lowbed trailer showing equalization via mechanical suspension

🔹 Why Axle Spacing Matters

Axle spacing determines how vertical and longitudinal loads are shared among suspension systems. It affects braking stability, tire wear, ride comfort, and turning radius.

⚙ Load Distribution Basics

In a 3-axle system the central axle usually carries slightly more load due to equalizer geometry. Increasing spacing allows more independent articulation → better road contact and lower frame stress.

📏 Mini Converter: Axle Spacing → Estimated Turning Radius

Estimated Turning Radius: 0 m

📊 Typical Configurations

| Trailer Type | Axle Spacing (mm) | Ride Characteristics |

|---|---|---|

| Standard 3-Axle Semi | 1310–1360 | Balanced comfort & load sharing |

| 4-Axle Lowbed | 1360–1420 | Improved stability, longer wheelbase |

| Modular / Extendable | 1500+ | Better articulation, wider drag radius |

🧭 Dynamic Stability

Narrow spacing = harsh ride, acts like rigid beam. Wide spacing = better articulation but larger turning radius and bending moment. Ideal is the “phase delay” effect — each axle absorbing road input sequentially.

💡 Suspension Type Interaction

- Mechanical: Best around 1350 mm spacing.

- Air Suspension: Can run closer because load levelling is independent.

- Hydraulic: Spacing based on geometry, not equalizer action.

🌍 Real-World Insight

4-axle lowbed with 1360 mm spacing shows **8–10% better tire wear distribution** and **5% shorter braking distance** vs. 1200 mm spacing due to smoother articulation.